Product Information

Excellent products and considerate service

Features Of Automatic Feeding CNC Machine With Panel Furniture Production Line:

1. Highly automated nesting solution with automatic loading and unloading system. The complete work cycle of loading, nesting, drilling and unloading is carried out automatically, which results in maximum productivity and zero down time.

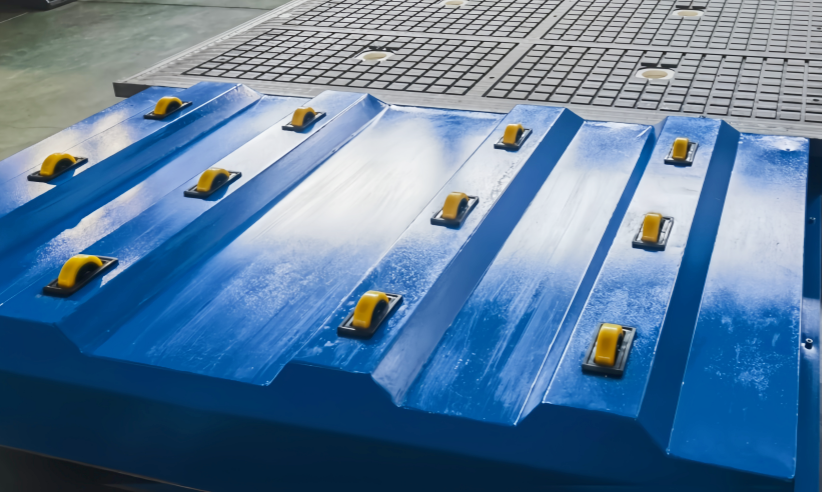

2. Humanizing design of the machine control interface,very simple to operate, requiring only minimal training of operator, do not need specialized operation technical personnel, high efficiency.

3. World‘s first class components - Italian high-frequency electro spindle, Taiwan SYNTEC control system, German servo motors and drivers, high precision planetary gear reducers, stable performance and long service life.

4. The world leading vacuum table, high adsorption capacity, can be strong adsorption of materials of different sizes, density, no deformation.

5. Truly versatile-nesting, routing, vertical drilling, carving, side milling and edge grinding all in one. It is well-suited for panel furniture, office furniture, cabinets production.

| Working Table Size(mm) | 1300*2500*300mm(can be customized) |

| Machine Type | cnc router |

| Number of Axes | 3 |

| No. of Spindles | 3 |

| CNC or Not | cnc |

| Weight (KG) | 2000 |

| Warranty | 1 Year |

| Key Selling Points | Sustainable |

| Range of Spindle Speed(r.p.m) | 1 - 18000 rpm |

| Positioning Accuracy (mm) | 0.03 mm |

| Travel (X Axis)(mm) | 1300 mm |

| Travel (Y Axis)(mm) | 2500 mm |

| Repeatability (X/Y/Z) (mm) | 0.03 mm |

| Spindle Motor Power(kW) | 9 |

| Voltage | 220v/380v |

| Dimension(L*W*H) | 1800*3000*1500 |

| Power (kW) | 25 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox |

| Product name | Cnc Router Wood Door Making Machine |

| Spindle | 9kw Air Cooling Spindle |

| 9kw Air Cooling Spindle | Syntec Control System |

| Syntec Control System | T.slot Table |

| Motor | Servo Motor |

| Inverter | Fuling Inverter |

| Software | ArtCam/TYPE3/Ucancam |

| Guide rail | Taiwan Hiwin Square Guide Rail |

| Transmission | Taiwan TBI Ball Screw |

| Applicable Material | wood, styrofoam (EPS), nonmetallic carbonation materials, density board, aluminum, copper,MDF, HDF, PVC, paraffin wax, gypsum,lamp,ceramic,etc. |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Home Use, Printing Shops, Construction works , Advertising Company |

Application

1. Furniture: Cupboard, wardrobe, panel furniture, office furniture, solid wood furniture, wood door, table, chair, door and window.

2. Woodwork: Sound box, game machine box, computer desk, sewing machine table and musical instrument.

3. Panel Machining: Insulating parts, plastic and chemical parts, PCD, inner body of bullet train, bowling ramps and stairways, carbonization mixtures such as compact board, phenolic resin, epoxy resin, ABS, PP and PE.

4. Decoration Industry: Carving, milling and cutting processing of acrylic, PVC, density board, artificial stone, PMMA, plastic and soft metal plates including copper plate and aluminum plate.

Production Details

TEI brake pad brake disc brake

Independent labeling unit can move quickly, when the machine is cutting and drilling,at the same time, it can identify plate in advance, and automatic label the code to the sheet, the operator just need to upload the materials, no need other work, so that to be further freeing up labor.

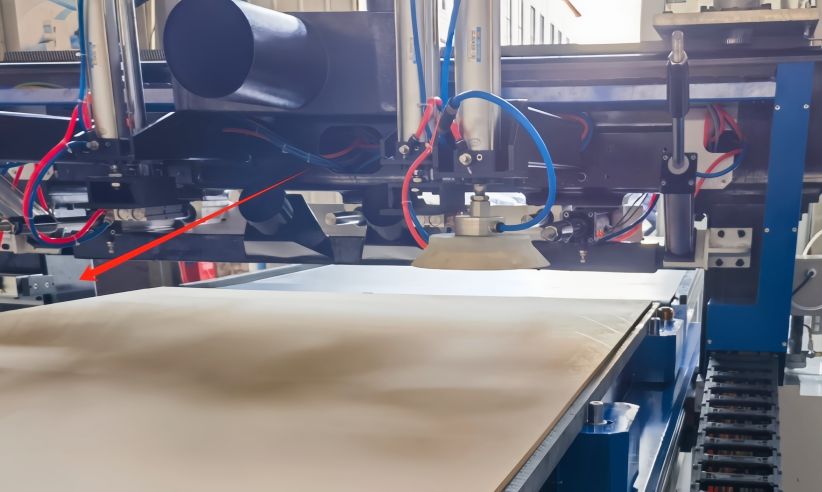

Automatic Loading System

The automatic loading system is consist of a lifting platform which support and raise the stack of material to height same the CNC router machine's vacuum bed, which is monitored with optical sensor.

Optical Sensor

When one piece of material is taken to process, then the Hydraulic Platform will go up, when it arrival to the senor, it will automatic stop and wait the Suction Cup Load System to come.

Pedal Control

It is one remote control for the Hydraulic Platform to up and down to load materials.

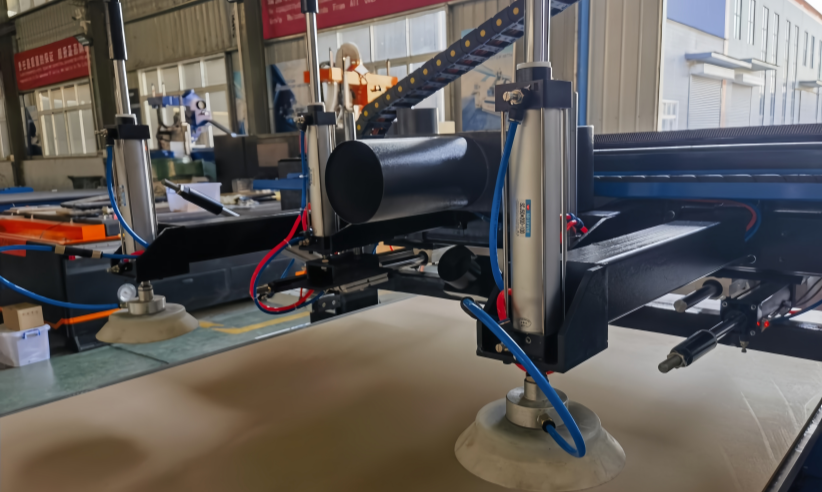

Suction Cup Load Device

The suction cup load system is installed on the gantry, it can automatic go to hydraulic platform to grab the board, then drive it to the working table.

Automatic Loading Auxiliary Device

When the suction cup load a sheet, the auxiliary device will help to reduce resistance and more easier to travel.