Product Information

Excellent products and considerate service

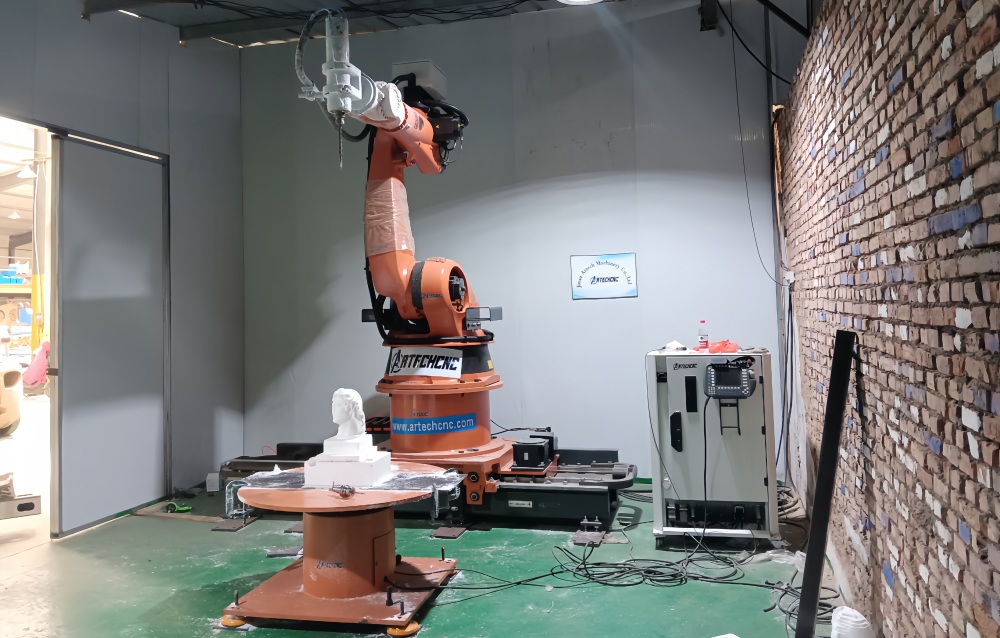

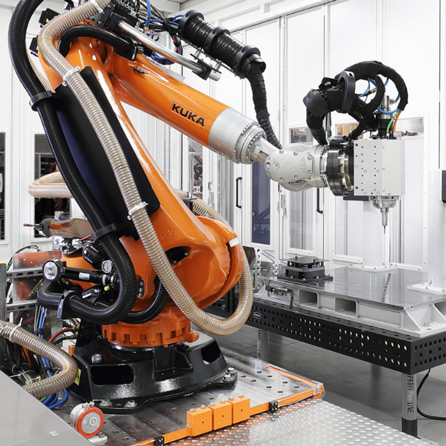

Cnc milling robot is the process of cutting material from a mold to sculpt a specific or complex shape using any material from plastic, metal, foam, wood to alloys. Milling robots can make the exact cuts and the precise movements necessary to produce the highest quality parts. Generally this process is based on two stages where the first consists of the rapid and cost-effective way of eliminating material giving way to the second stage that is the finish of the structure based on dimensions, degree of surfaces that determine furrows in detail, profiles, openings and even three-dimensional surface contours.

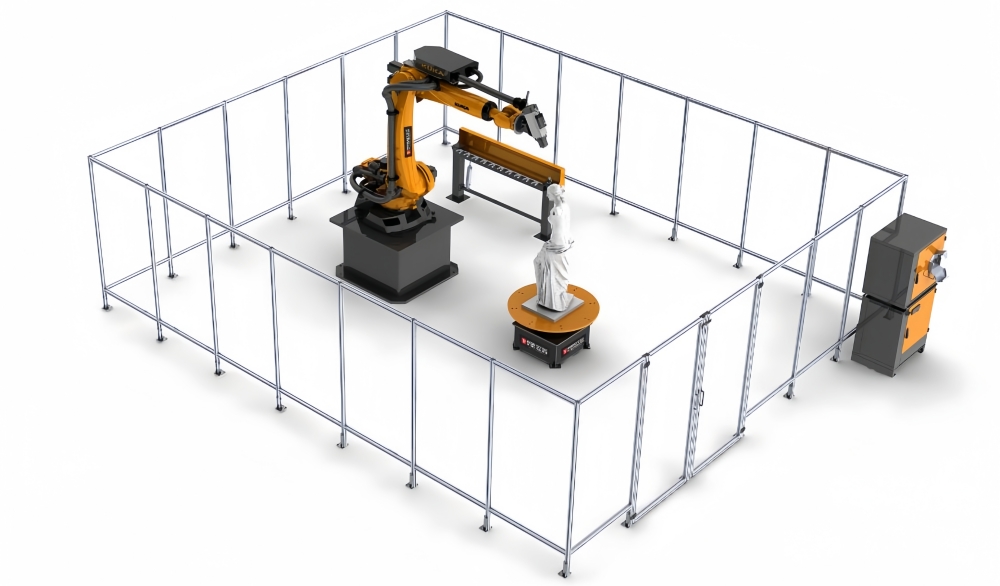

Automated robot machining systems can be flexible and versatile tools designed to address the removal of specific material.Robot arm cnc milling generally perform a routine following PTP movements (point to point) or a linear or curved group in 3d programming this process only once throughout the life cycle providing a large workspace; This robotic solution is one of the most profitable and considerably more flexible. The robot milling work cells are designed to have multi-part accessories.

| Load(refers to the load of point P at the foremost end of the 6th axis) | 210kgs | |

| Supplementary load | 50kgs | |

| Total load | 260kgs | |

| Weight | 1068kgs | |

| Motion axis | 6 | |

| Max.envelope | 2696mm | |

| Repeat accuracy | 〈+/-0.06mm | |

| Flange (on the 6th axis) | DIN ISO 9409-1-A50 | |

| Controller | KRC4 | |

| Installation position | On the ground | |

| Motion parameters of each axis | Range of motion | Speed |

| Axis 1 | +/- 185° | 1123°/s |

| Axis 2 | -5°/-140° | -5°/-140° |

| Axis 3 | +155°/ - 120° | 112°/s |

| Axis 4 | +/-350° | 179°/s |

| 179°/s | +/- 125° | 172°/s |

| Axis 6 | Axis 6 | 219°/s |

Feature

Plastic trimming

A robotic cell next to a 6-axis milling robot can be the ideal system for the manipulation of this material, it will provide a stable process and of optimum precision in the cut of milling, using a low power when trimming pieces of low volume, improving the control of noise and dust, with faster and cheaper deliveries, minimal maintenance and putting the system back on track in less time.

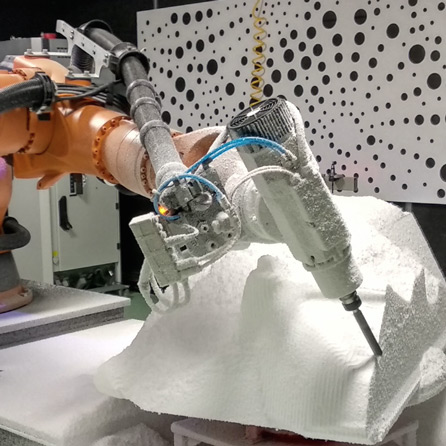

Polystyrene

This is one of the most used and lowest cost materials. The milling of this material with an industrial robot provides greater versatility and flexibility when performing complicated movements when carving the piece. This type of material can be processed by water jet cutting and injection molding.

Robot on linear track

Perform milling on a linear track it provides stability and strength by providing production lines and work cells flexibility,speed and precision. These positioning systems (linear track) will allow the robot to perform several processes in different directions, motivating this seventh axis to minimize cycle time, maximize efficiency and save costs.

Robotic hot wire cutting

The hot cutting wire meets high machining standards because it is fast and efficient when it comes to forming a part; obtaining less waste of material and improving the time of machining, can be adapted to different lengths by adding a rotating table.

Marble machining

The robotic automation of the milling of the marble together with a simple software will allow to maximize the production especially in the finishing phase with high levels of precision that will save time in processes of manufacture of sculptures,

engravings, restoration, etc.

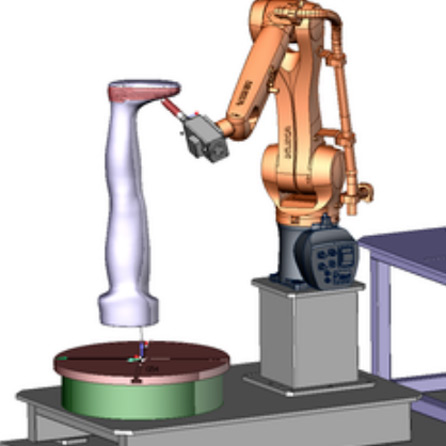

Medical

Modeling an orthopedic prosthesis is carried out by a milling system which is complemented by new technologies supported by CAD / CAM provides the advantage of making orthopedic functional prototypes of all kinds.

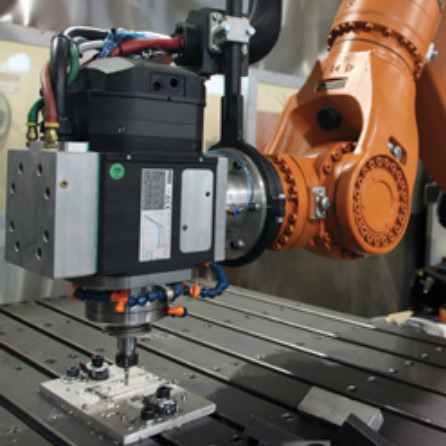

Metal milling

The solution of robotic milling in metals has had great advances adapting easily to the production lines offering a safe machining, resistant, with greater flexibility and repeatability, achieving efficiency in the continuous cycle times, mainly when working on large parts.

Nautical/Boat milling

Using robotic automation of milling for the manufacture of yachts has allowed this industry from its production lines and with the collaboration of an interface that processes its information through CAD / CAM; designing and modifying prototypes faster, reducing production time maintaining a high level of accuracy.

Architecture

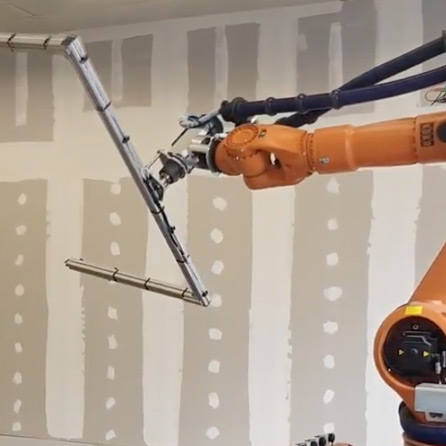

The architectural designs made with robots have the ability to mill and create structures with very defined contours thanks to the use of cutting tools and modeling programs controlled by the robotic system adapting to any material and transition; promoting new technological developments for construction.

Art

Through the use of industrial robots, a computer-assisted system, the integration of a machining tool and devices that complements the milling system, it has been possible to create, manufacture and imitate all kinds of art from painting, drawing, writing and sculpture, taking care of every detail when shaping the finished piece with optimal precision.

Carbon Fiber Trimming

A system of milling allows to work in pieces of forms and compound materials, light and resistant like the fiber of carbon, that can be drilled, contoured, mechanized or cut; With the right tool performing the process at high speed to achieve clean cutting profiles and double the volume of machined products.

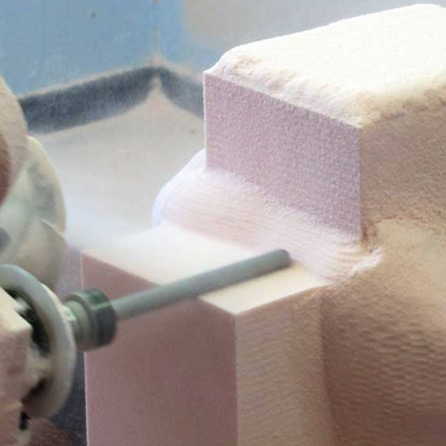

Foam sculpting

Robotic milling systems together with a cutting tool design that provides greater benefit, can offer flexibility to process materials such as foam and create large-scale sculptures up to 34 feet long, following a continuous path at high speed.

Application Fields

Senior sculpture handicraft, wood carving handicraft processing, non-metallic mold machining, casting products, sanitary ware products model processing, etc.

Kuka cnc milling robot working process:

1:Through the three-dimensional modeling software (such as ZBRUSH, FF engraving pen, 3D Max, Rhino, Maya, etc.) designed to get 3D model of the product, or by 3D scanning export 3D data sample.

2:With multiple spindle automatic programming software (SmartMill1.9) transferred to 3D data (STL) make up processing tool path , calculate the processing code (G code)

3:(RobCode) software will be 3-5 axis machining cutter path carved into robot trajectory.